It is essential to choose the right bearing for longevity, efficiency, and reliability of your machinery. No matter what type of machine you are operating, the right bearing will greatly improve the quality of your equipment. In this guide, we will provide you with complete information about choosing the right bearing for your machinery and the most important details to consider when selecting a bearing.

Table of Contents

Bearings – The backbone of machinery

Bearings are mechanical devices that allow for rotational or linear movement, bearings reduce friction between moving parts. Bearings support loads and allow for motion. Bearings are essential for a variety of applications, from automotive engines to industrial machinery

Key Points to Consider When Choosing a Bearing

1. Load Capacity

The bearing is designed for a specific load. To select the appropriate bearing, it is necessary to calculate both the radial load (perpendicular to the shaft) and the axial load (parallel to the shaft) on the machinery. Choosing a bearing with an inadequate load capacity will lead to bearing failure.

2. Speed and RPM

The speed at which your equipment operates affects the speed of the bearing. High-speed applications require bearings that are designed specifically for that speed. They allow for higher levels of rotational speed without losing the shape or performance of the bearing.

3. Environmental Conditions

Bearings are selected for use based on the environmental conditions which the application will be used. Many factors, such as extreme temperatures and exposure to moisture, dirt, or chemicals, are considered. If these can be an issue, sealed or shielded bearings are always recommended as they provide additional protection.

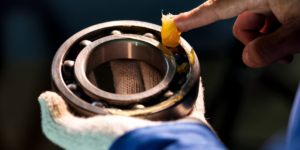

4. Lubrication

Proper lubrication is essential to keep the minimum friction. You may also have to use grease or oil lubrication. Grease is only appropriate for low-speed, low-load applications, while oil is highly recommended for high-speed, and/or high-load applications.

5. Precision and Tolerance

Some applications, such as aerospace or robotics, need bearings that are more about precision and tolerance than load or speed. Knowing how much you need every part to function as designed allows the machine to perform better while providing workable life and longevity.

Types of Bearings and Applications

- Ball Bearings

The ball bearing is the most common. This type of bearing can be used in various applications of various speeds, loads, and is capable of handling radial and axial loads. Decent Machinery has a variety of ball bearings, such as deep groove and angular contact ball bearings.

- Roller Bearings

Roller bearings use cylindrical rollers to allow for carrying heavier radial loads. These bearings are generally used when the load capacity becomes very heavy. The most commonly used roller bearings are cylindrical and tapered.

- Thrust Bearings

Thrust bearings are specifically designed for adjusting the axial load. They are typically used in automotive and industrial applications that require axial load. Decent Machinery also has thrust ball bearings to meet these specifications.

- Spherical Bearings

Spherical bearings will allow for the allowance of misalignment of the shaft and housing, This is useful in applications where misalignment or deflection of the shaft is not your preferred setting.

Decent Machinery: Your Trusted Bearing Supplier

Decent Machinery is known for being a trusted supplier of high-quality bearings and machinery parts. Some core products Decent Machinery offers include:

- Deep Groove Ball Bearings: These are recommended for high-speed running and applications that require low-noise.

- Angular Contact Ball Bearings: Recommended for axial and radial loads that act together.

- Self-aligning ball bearings: Used to adjust the misalignment of the shaft and housing.

- Thrust Ball Bearings: This type of bearing is designed to support axial loads in many industrial applications.

- Cylindrical and Tapered Roller Bearings: They are an excellent choice for heavy radial loading.

- Spherical Roller Bearings: These are capable of support the high radial loads and secondary axial loads.

Our dedication to quality and customer service makes us a popular choice for many industries around the globe.

Conclusion

Selecting the correct bearing is important to ensure your machinery is performing at its best. By considering the right factors, typically including load capacity, speed, environmental conditions, lubrication, and precision, you can make a better decision. You can trust to get the appropriate bearings for your purposes from reputable companies like Decent Machinery.

FAQs

1. How can I choose the proper bearing size for my machinery?

You should measure the diameter of the shaft and the bore of the housing (a comfortable fit associated with a proper width). Next, you can consult bearing manufacturers and select a bearing size.

2. What is the difference between sealed bearings and shielded bearings?

Sealed bearings have a rubber seal on each side which assists in keeping contaminants and grease in or out of the bearing. The shielded bearings are made with metal shields which are not as efficient as seals. Sealed bearings give a higher level of protection in adverse conditions.

3. Can I use different bearing types for different applications?

Versatility of bearings is important to consider for different applications. You should also consider load, speed and environmental conditions while choosing bearings.

4. How do I prolong the life of my bearings?

You can prolong the life of bearings by regularly maintaining, lubricating, and operating within appropriate load and speed limits. This will ultimately lead to the best bearing life.