Angular Contact Ball Bearings

Home >> Industrial Bearings >> Ball Bearings >> Angular Contact Ball Bearings

Have Query?

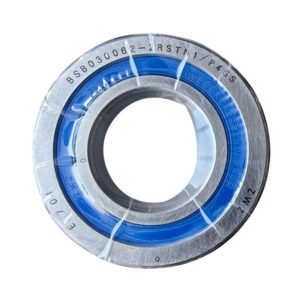

Best Angular Contact Ball Bearings For Machines

Angular contact ball bearings are equipped to bear combined loads. Offsets between inner and outer raceways offer axial shaft mounting in either direction. The use of this type of bearing is abundant and found within aerospace and automotive engineering. We shall go further into detail concerning ball bearings here for your information.

Design of Angular Contact Ball Bearings

These bearings are designed to precise requirements for use in a broad selection of high-load applications. It consists of the cage, ring, and ball material. Unlike radial bearings, which possess a contact angle of only 8 degrees, they possess a contact angle of about 15 and 25 degrees that balances tilting motion. The other reason is that angular contact ball bearings are manufactured with one raised shoulder on the outer ring, so they are ideal for more loads and higher speeds.

What is the significance of Angular Contact Ball Bearings?

One of the most important types of bearings that are used in a wide variety of applications is the angular contact ball bearing. They are typically used in applications that demand high precision and load-carrying capacity. They are also used in applications where low noise and low friction are needed.

Advantages of Angular Contact Ball Bearing

The application of ball bearings has many benefits. Some of the benefits include:

- Increased strength: These bearings are designed to carry heavy loads. In order to distribute the weight evenly and prevent the balls from touching each other, a metal cage is used to keep the balls apart in the bearing. Therefore, the bearing becomes stronger and can withstand heavier loads for longer periods of time.

- Reduced friction: These bearings have less friction compared to the other types of bearings. This is due to the manner in which the metal cage separates the balls. Reduced friction is accomplished through the helping of the cage in reducing the contact between the balls and bearing surface.

- Greater efficiency: Since they have lower friction, they are more efficient than other types. This means that they require less energy to operate, and this can lead to reduced operating and energy costs.

- Less Axial Space: It can be used efficiently without requiring multiple bearings in such cases when there is limited axial space.

- Designed for High Rigidity: Best suited for applications where high rigidity and precision are important.

What are the applications of Angular Contact Ball Bearings?

These bearings contain balls that, at a specific point on the bearing, touch the inner and outer raceways. Both high axial and high radial loads can be handled by these bearings. To neutralize any forces that may be applied on the bearing, they are used in pairs in most cases. Some of the uses of these ball bearings include electric motors, compressors, gearboxes, pumps, and fans. Some of the typical applications include:

- Carrying heavy radial loads on gearboxes and electric motors

- To carry heavy axial loads on equipment such as pumps and compressors

- In order to destroy any possible forces that may act on the bearing when used in pairs.

Choose Decent Machinery for Angular Contact Ball Bearings!

We made the definition and working of angular contact ball bearings clear to you. With the right maintenance and care, these bearings can be used in various applications and enjoy a long service life.