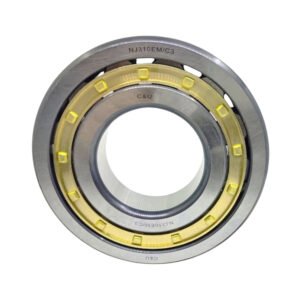

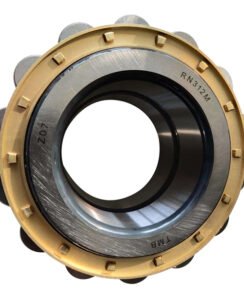

Cylindrical Roller Bearings

Home >> Industrial Bearings >> Roller Bearings >> Cylindrical Roller Bearings

Have Query?

Best Cylinderical Roller Bearings For Machines at affordable prices

The CRBs are special types of rolling contact bearings constructed to carry high radial loads with very low friction. They are optimally designed and constructed to withstand heavy loads at high speeds, namely conditions experienced by machines.

Normally a cylindrical roller bearing consists of several cylindrical rollers which make linear contact with the raceways, and in this way, generate great radial loads. The arrangement of the rollers twists the low weight to gain high-speed rotation. Most of these bearings have separable units, in which case, the inner and outer rings can be fitted with ease while also enabling easy mounting and dismounting.

Types of Cylindrical Roller Bearings

Single-Row Bearings: A bearing with a single row of rollers is called NU, NJ, NUP, N, or NF, depending on rib configurations. It is often employed where axial displacement is insignificant.

Double-Row Bearings: The two roller rows give these bearings an increased radial load capacity and rigidity, making them suitable for applications like machine tool main shafts.

Four-Row Bearings: These bearings can take very high radial loads and are mostly found in heavy machinery such as rolling mills.

Full-Complement Bearings: These bearings, which without a cage retain the maximum number of rollers, have the highest load capacity but may compromise higher speed performance due to increased friction.

Thrust Bearings: Built to withstand axial loads in one direction, these bearings are used in applications of precise motion control.

Applications

Cylindrical roller bearings are widely used in a range of industries because of their very good load capacity and efficiency. Their applications include:

- Electric motors: for mounting high speed rotation and heavy radial loads.

- Gearboxes and transmissions: for accommodating loads of substantial radial magnitude within small spaces.

- Wind turbines: for heavy radial loads and operations in a very harsh environment.

- Machine tools: for high rigidity and accuracy in the main shafts.

- Railway wheelsets: for heavy radial loads within railway vehicles.

- Pumps and compressors: for ensuring smooth operating conditions under heavy radial loads.

Advantages

- High Radial Load Capacity: Provides radial load efficiency because of larger contact area of rollers with raceways.

- Low Friction: Well efficient friction loss during operation.

- High-Speed Capability: Offers it for a high-speed rotation.

- Compact Design: Gives a huge load bearing within a compact design, ideal for areas where space is a hindrance for installation.

- Versatility: Various configurations are available in accordance with application-specific requirements.

Maintenance and Lubrication

Essentially, care and lubrication of the cylindrical roller bearing are vital for valuable performance, increased service life, and good output. Lubrication may consist of oil and grease, which should suit the bearing application according to parameters like speed, temperature, and load. Therefore, regular monitoring and proper lubrication are very important for the bearing.

Common Causes of Bearing Failure

There are many reasons why cylindrical roller bearings fail, including:

- Contamination: Bearing surfaces are damaged by the foreign bodies.

- Improper Mounting: Misalignment from improper installation will cause premature wear.

- Misalignment: It causes an uneven load distribution and increased stress on the bearing.

- Corrosion: It may cause deterioration in materials due to moisture or corrosive environment around it.

- Overheating: The higher temperature causes the lubrication to break down and damages the bearings.

- Excessive Loads: Exceeding the bearing load capacity will cause fatigue and failure.

FAQs

Q1. What differentiates a cylindrical roller bearing from a ball bearing?

A: Essentially, cylindrical roller bearings are made for handling heavy radial loads, while ball bearings are reasonably better for lighter radial loads at high speeds.

Q2. Are axial loads allowable in cylindrical roller bearings?

A: Models like the NUP and NJ types can take an axial load in one direction.

Q3. Which materials are used to make cylindrical roller bearings?

A: The commonly known materials are chrome steel (AISI 52100), stainless steel, and ceramic. These are used based on the load carrying capacity, corrosion resistance, and operating conditions that need to be considered.

Q4. How frequently should the cylindrical roller bearing be lubricated?

A: Lubrication frequency will depend upon running conditions, nature of the lubricant used, regular maintenance intervals, and monitoring providing help for determining an appropriate relubrication schedule.

Q5. Is the cylindrical roller bearing suitable for high-speed applications?

A: Yes, cylindrical roller bearings are specifically designed for high-speed performance and would serve applications such as electric motors and turbines.