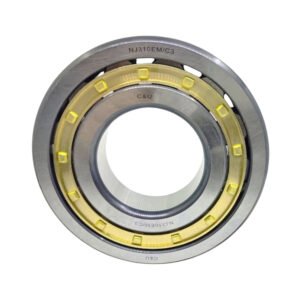

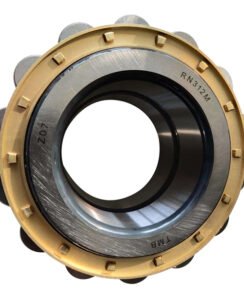

Cylindrical Roller Bearings

Home >> Industrial Bearings >> Roller Bearings >> Cylindrical Roller Bearings

Have Query?

Best Cylinderical Roller Bearings For Machines at affordable prices

The cylindrical roller bearings are roller contact bearings. They are typically designed to withstand heavy loads and high speed.operations.

Types of Cylindrical Roller Bearings

There are mainly four types of cylindrical roller bearings designed for diverse applications.

Single-Row Bearings: The bearings with a single row of rollers include the types of NU, NJ, NUP, N, or NF. They are normally used in applications where axial displacement is insignificant.

Double-Row Bearings: The double-row structure offers an escalated radial load rating and rigidity, allowing them to meet applications like machine tool spindles.

Four-Row Bearings: These bearings can take considerable radial loads and are mostly found in heavy-duty machinery such as rolling mills, grinding mills, crashers

Full-Complement Bearings: These bearings have the maximum number of rollers mounted without a cage. They offer the highest radial load rating, but lower speed capacity due to increased friction.

Applications

Cylindrical roller bearings find their applications in a range of industries due to their immense load capacity, high speed and efficiency. Their applications include:

- Electric motors: Supporting high-speed rotation.

- Gearboxes and transmissions: Supporting substantial loads in limited space.

- Wind turbines: Providing high radial load handling and durable operation in an awkward, inaccessible position.

- Machine tools: Offering high rigidity and accuracy on the main shafts.

- Railway wheelsets: Delivering high radial load capacity in railway vehicles.

- Pumps and compressors: Ensuring smooth operation under excessive vibration.

Maintenance and Lubrication

Scheduled maintenance is pivotal to cylindrical roller bearings’ optimal performance. It serves to ensure the bearings’ rotation rating, load capacity and designed service life. Lubrication in the form of oil or grease should strictly match the exact bearing application including speed, temperature, and load rating.

Common Reasons of Bearing Failure

There are many reasons why cylindrical roller bearings fail, including:

- Contamination: Bearings can be damaged by contaminants such as mud, sand and iron filings. These foreign materials impede the bearing rotation, and accelerate bearing wear.

- Improper Mounting: Improper alignment causes an uneven load distribution that increases stress and friction on the bearing.

- Corrosion: Moisture and corrosive environments can speed up material degradation, and therefore reduce the expected bearing life.

- Overheating: When exposed to sustained excessive temperatures, the lubricant inside the bearing will break down and evaporate, resulting in bearing damage.

- Excessive Loads: Bearing selection must meet the requirements of equipment. Loads beyond the rated capacity will give rise to premature bearing fatigue and failure.

FAQs

Q1. What is the difference between a cylindrical roller bearing from a ball bearing?

Cylindrical roller bearings are specially designed to support heavy radial loads, while ball bearings perform better under lower radial loads and high-speed application with lower friction.

Q2. Are axial loads allowable in cylindrical roller bearings?

NUP and NJ types are able to sustain an axial load in one direction. Whereas, other types can support axial loads when mounted in pairs.

Q3. Which materials are used to make cylindrical roller bearings?

The common materials are chrome steel (AISI 52100), stainless steel, and ceramic. These are used based on speed and load capacity, corrosion resistance, and other operating conditions.

Q4. How frequently should the cylindrical roller bearing be lubricated?

It’s not fixed. Lubrication frequency depends on the bearings’ running conditions and state of lubricant in use. Preventive maintenance and routine equipment service help to set an appropriate relubrication schedule.

Q5. Is the cylindrical roller bearing suitable for high-speed applications?

Yes, cylindrical roller bearings are specifically designed to support heavy radial loads and high-speed rotation such as motor spindles and machine tools.