Description

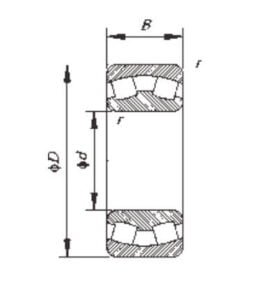

The TWB 22314CE/C3W33 spherical roller bearing (70mm x 150mm x 51mm) is a high-quality, precisely engineered component for excellent performance in heavy-duty applications. For radial and axial load settings, the bearing is commonly applied in the mining, construction, automotive, and manufacturing industries. The robust design of the 22314CE/C3W33 TWB bearing, with high load capacity and self-aligning feature, assures many years of operation, less maintenance, and great durability.

Being a spherical roller bearing, the TWB 22314CE/C3W33 is meant to carry high radial loads and also moderate axial loads in both directions. Its slantwise design and material composition allow it to perform efficiently under harsh operating conditions, which makes it the bearing of choice for heavy-load machinery and equipment.

Main Features of TWB Bearing

Enhanced Load Capacity:

The 22314CE/C3W33 TWB spherical roller bearing is designed to support high radial loads, which makes it suitable for heavy-duty applications. Apart from this, it can also withstand moderate axial loads in both directions. This load combination is particularly useful in situations where both radial and axial stresses occur frequently, e.g., large machines, conveyor systems, industrial equipment, etc.

Self-Aligning Design:

One of the special qualities of this TWB bearing 22314CE/C3W33 is its self-aligning feature. The spherical rollers would allow it to align in cases of shaft misalignment or angular displacement. In the absence of such a self-aligning feature, traditional bearings get subjected to uneven wear and premature failure. More reliability in operation, therefore, and a more extended life for the bearing.

C3 Clearance:

With a C3 internal clearance, greater than that of a normal bearing, it is designed to accommodate a little more internal clearance between its members. This allows for thermal expansion and moderate misalignment, thus providing an advantage to the bearing under adverse conditions so that it is not set under abnormal heat or wear during high load operations.

Advanced Steel Cage Construction:

This bearing is made for rough conditions under which a pressed steel cage would guarantee even spacing among the rolling elements and safeguard against contamination. It therefore reduces friction, enhancing the bearing-ability and longevity by maintaining the consistency of roller alignment. The steel cage also shows resilience to wear and corrosion.

Durability and Longevity:

Made from high-quality steel, the 22314CE/C3W33 TWB bearing is meant to last. The design prevents unnecessary friction and wear that lead to the premature short lifespan of bearings. In the words of the bearing, it is strong enough to withstand situations of high-speed rotation, extreme temperatures, and heavy loads.

Seals and Protection:

This bearing has a W33-type lubrication groove and holes for retaining grease lubricants. This increases the bearing’s ability to withstand harsh conditions where dirt, dust, and other foreign particles may enter to damage the bearing elements. It can be further sealed if required by choosing different seals.