Description

Selected:

Product Specifications

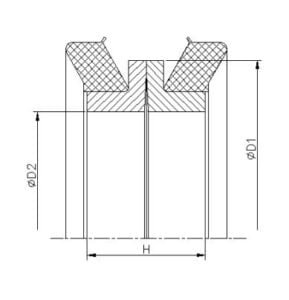

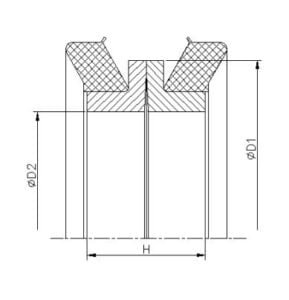

| Part NO. | CR18259 | |

| Type | DF Heavy Duty Application | |

| Dimensions | 50.5*65*18mm | |

| Application | Track Roller Assembling Travel Motor Assy Final Drive Assy Travel Reduction Gear | |

| Metal Ring Material | FC15Cr3Mo Cast Iron | |

| Metal Ring Hardness | HRC65-70 | |

| O-Ring Material | Nitrile/HNBR Shore A | |

| Linear Velocity | 3m/S | |

| Service Life | 5000-8000hrs | |

Bearing & Power Transmission Supplies & Services

© 2024, decentmachinery. All Rights Reserved

Developed By Boodlemart