Few parts in industrial machinery are needed or appreciated more than bearings. Bearings are the silent participants that really make our machines and systems rotate, reduce friction and withstand enormous loads. It is important to choose the right quality bearing because this choice has an impact on the performance and longevity of your equipment and bearing load capacity is one of the most important criteria for this decision.

In this detailed article, we will provide you with a comprehensive guide about the bearing capacity load and how to calculate bearing load, bearing load types, and how to choose the best bearing for your application.

Table of Contents

What is Bearing Load Capacity?

Bearing load capacity is simply the maximum amount of force a bearing which can handle safely and still operate properly. Those forces can come in various directions and intensity based on the machine design and method of operation. There are two type of primary loads:

Radial Load -This is a force that is applied perpendicular to the shaft. This is usually seen in motors and related applications in pulleys, rotating shafts, etc.

Axial Load (Thrust Load) – A force that is applied parallel to the shaft. This occurs in screw jacks, turbines, and pumps.

Some applications involve both loads, which means the bearing has to deal with more complex stresses with additional loads combined in different ways.

Types of Load Ratings

When it comes to bearing load capacity, two terms are important:

1. Dynamic Load Rating ©

This is the load that a bearing can withstand for a rating life of one million revolutions before fatigue also applies to the bearings in rotating or frequently moving applications.

2. Static Load Rating (C₀)

This is the maximum load that a bearing can take while stationary or while moving very slowly that will not cause permanent deformation of the bearing components.

If you choose bearing with insufficient ratings, it can lead to failure with wear, cracking, or deformation when loads are high or variable.

Type of Load Bearing by Bearing

Bearings are designed for specific loads, and whether they are radial or axial etc.:

Ball Bearings

A ball bearing accommodates fairly moderate radial and axial loads. They are often considered for high speed applications with lower loads.

Roller Bearings

Roller bearings will take higher radial loads, and or rollers such as cylindrical, tapered, or spherical rollers can be found in more demanding applications.

Thrust Bearings

Thrust bearings are designed to take thrust (axial load). They are found in gear assembly and vertical shafts.

Spherical Bearings

Spherical bearings can take misalignment and lots of combined loads. Spherical bearings are used in mining, heavy equipment, and off-road vehicles.

Profile of Time Extensive Variables that Affect Bearing Load Capacity

Different inside and outside variables will affect the capacity of the bearing when a load is applied:

1. Material Strength

Bearings made from the finest steel or composite ceramics tend to be more resistant to fatigue and failure. Additionally, it improves the heat treatments and crystallization will also enhance the surface hardness and durability of material. It helps to increase bearing life.

2. Size and Shape

Generally, the larger the bearings or those that have specific internal geometry in the form of thicker rollers or deeper grooves will have higher load limits.

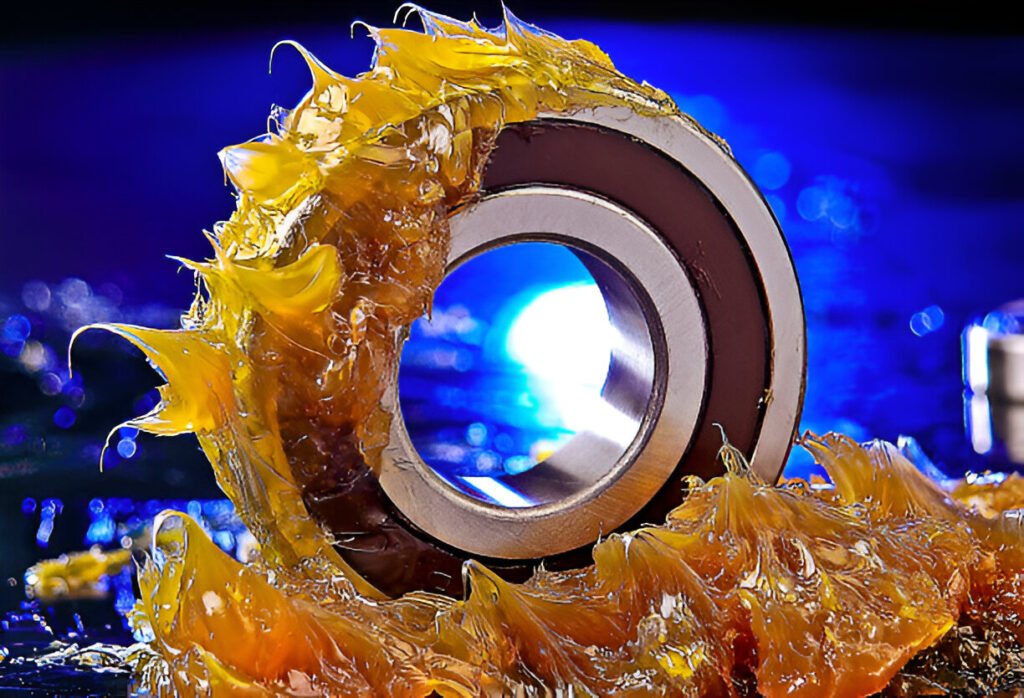

3. Lubrication

The right lubrication reduces both friction and wear. Without appropriate lubrication, the combustion can cause failure. Failure can occur at any load rating as indicated on any bearing due to the lack of lubrication, vibration, temperature change, contamination, and misalignments of the bearings acting upon the load rating in the desired application.

4. Application or Environment

If vibration, temperature, contamination, and misalignment are reduced in terms of applied load rating, a load rating will only assume an ideal situation. It is only prudent to add safety factors based upon the application!

What is Bearing Life?

The most popular use of bearing life calculations is represented by the L10 life equation. The L10 life equation assumes the predicted bearing revolves 1,000,000 times. The L10 life equation predicts the number of revolutions that will be experienced by 90% of one of the world’s identical bearings before exhibiting fatigue at a given load:

L10: (C / P)³ * 1,000,000 revolutions

Where: C = Dynamic Load Rating, and

P = Equivalent Dynamic Load experienced by the bearing

The L10 life equation is used by an engineer to ensure a bearing supplier has provided a bearing that is capable of the capacity specific to how the load is being applied. As you apply more load, you will reduce your revolutions per minute (rpm).

Real-World Example: Load Capacity in a Conveyor System

In a bulk material carrying conveyor system the bearings should be account for the shaft weight, the belt tension, and the load of the material moving through. If the bearings are overloaded then they can wear out quickly and it can breakdown the system and production delays.

Choose a bearing with the proper load rating helps you achieve long-term reliability and reduced maintenance. Spherical roller bearings or tapered roller bearings are generally preferred in such applications as they afford the highest radial load capacity and the capacity to take up some misalignment.

Tips for Selecting the Right Bearing for Load Capacity

To bring your bearings to the next level, you should consider the following tips:

Establish Your Load Conditions

You should understand if your application is acting on the bearing in radial, axial or a combination of both. Also, make sure to quantify the force exerted during operations.

Understand Your Speed and Duty Cycles

Bearings for high-speed operations will require different load considerations than slow speed, high torque environment.

Consider The Environment

Dust, moisture, extreme heat, or corrosive materials will all impact performance of bearing. Use the correct seals, materials, and lubrication for your specific applications.

Do Not Over Spec

Oversized bearings drive additional cost and unnecessary weight. If we ever want to exceed in any performance window unless safety regulations should be explicitly in place.

Use Application Tools and Software

Load Calculating Tools and CAD-based selectors can provide reliable predictions and comparisons between bearing choices.

Mistakes to Avoid When Choosing Bearings

Failure to Account for Axial Loads – Axial loads does not be given the attention they deserve. Such is the case for vertical shafts, where axial loads are either missed altogether or underestimated.

Failure to Consider Lubrication – The effects of the wrong grease or oil can be reduced the capacity of bearing due which increase the friction.

Assuming Only Static Loading – In some cases, dynamic or shock loads occur during start/stop conditions.

Failure to Mount Bearing Accurately – Installing a bearing improperly can lead to misalignment, which leads to uneven load distribution.

Conclusion

It is important to understand the bearing load capacity for a practical and not an academic consideration. Additionally, it will allow you to achieve the longest equipment life, efficient operations, and safe workplace practices. By using the correct bearing, you eliminate unnecessary maintenance / prolong failure definition time.

Whether you are embarking on designing a new machine or replacing certain components, having accurate information about what type of load is present, together with operating speeds and the environmental conditions will help you to choose the right bearings. They can provide expert guidance, high-quality products, and solutions tailored to your requirements.

Need Bearing Solutions From a Trusted Expert?

Decent Machinery is a leading global supplier of industrial bearings and motion components. We carry a sizable selection of bearings designed for high performance and long service in demanding applications.

We will help you with calculating bearing loads and finding the right bearing to fit your application, then we will guide you through all the stages you need help with. Our excellent technical team will assist in all aspects from your selection in catalogs to custom solutions you desire.

Contact us now for your bearing that is designed for load, speed and durability.