DO Type

Home >> Duo Cone Seals >> DO Type

Have Query?

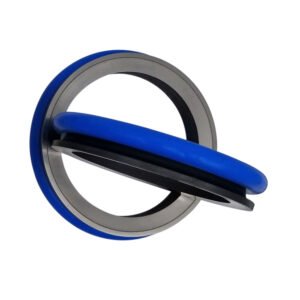

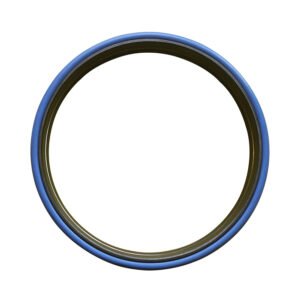

The DO type is the most used mechanical face seal type, which consists of two identical metal rings and two elastomer O-rings. This compact mechanical seal is primarily intended for constant low speed, heavy load application. High wear resistance, automatic compensation telescopic after the end face has wear, reliable operation, compact structure, and low maintenance are the advantages of using this type of seal.

Duo cone seals are widely used in many types of machinery operations, e.g. coal mining machinery and machinery used in infrastructure, including bulldozers, scraper conveyor head (tail) sprocket assemblies, and tunnel boring machines.

Operating Principles and Longevity of Do Type Duo Cone Seals

The rotation of the shaft also causes the sealing ring that encompasses it to rotate while the second sealing ring remains unchanged. The rotational torque means that axial pressure acts automatically on the sealing ring interface, which increases the sealing efficiency by pushing out any contaminants and fluids. As a result, one sealing ring rotates in relation to the other, and the O-rings are compressed against each other, which establishes a sealing force across the two sealing faces.

The sealing faces are continually held in contact with one another, so dirt, sewage, and other contaminants cannot enter from the outside world. As the sealing faces wear evenly over time, the O-rings release their stored elastic energ. These provide axial compensation while keeping the duo cone seal effective for as long as possible. The typical service life goes up to 5000 hours.

Standard and Custom Designs of Do Type Duo Cone Seals to Meet Your Requirements

At Decent Machinery, we provide a wide range of DO type duo cone seals. We offer our clients a variety of applications to choose from. We have different types of face seals, making sure that we meet our client’s specific operational needs and demands.

We also provide you with customised designs if our standard products are not satisfactory for you. We tailor your requirements and create face seals according to your specific needs. We believe in providing top-quality, trustworthy solutions. Decent Machinery makes sure that our clients are satisfied, regardless of the application type.

Get in Touch With Decent Machinery to Buy DO Type Duo Cone Seals

Want to buy DO Type duo cone seals but confused where to buy from? With a variety of options and websites available in the market, Decent Machinery stands out as the best provider for DO Type Duo Cone seals.

Get your specific type of seals today from Decent Machinery or contact us at + (86)15807142157.

You can also email us at info@decentmachinery.com and customise your specific type of DO type seal.

Frequently Asked Questions on DO Type Seal

Q1. What is a DO Type Seal?

A: A DO Type seal is made up of the two metal parts, namely, 15Cr3MoNi alloy cast iron and two rubber O’Rings. This is a standard floating seal.

Q2. What applications are DO Type Seals designed for?

A: DO Type Seals are found in equipment such as bulldozers, scraper conveyors, coal mining equipment and tunnel boring machines.

Q3. How long should a DO Type Duo Cone Seal last?

A: The seals should last around 5000 hours under normal operation.

Q4. Can I get a DO Type Seal made in custom designs?

A: Yes Decent Machinery can custom design seals if the standard products do not satisfy your operational needs.