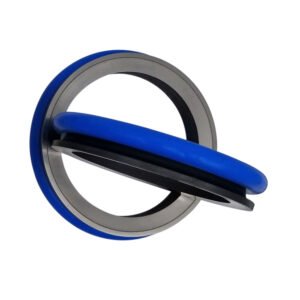

Duo Cone Seals

Home >> Duo Cone Seals

Have Query?

Duo cone seals are a reliable sealing solution for the final drives and track rollers of earth-moving machines such as wheel loaders, articulated road trucks, bulldozers, motor graders, excavators, crop harvesters and screw conveyors. Their simple yet robust structure delivers effective sealing performance by preventing lubricant leakage,while blocking external contaminants from entering the machine’s transmission system.

At Decent Machinery, we are well equipped to supply all types of duo cone face seals compatible with the majority of aftermarket part numbers. These seals are manufactured to rigorous standards to meet the requirements of major construction machinery brands, including Caterpillar, Hitachi, Komatsu, Volvo, John Deer, Liebherr, Bauer, LS and more.

Best Duo Cone Seal For Machines at affordable prices

Decent Machinery supplies duo cone seals of the highest quality. Here we offer mechanical face seals designed for a broad array of equipment and applications. Every seal undergoes rigorous testing and inspection to the highest standards, ensuring that our customers are getting the most competitive and reliable heavy-duty seals on the market.

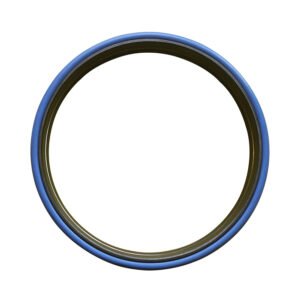

Specifically designed for heavy duty, rotating applications, Decent Machinery’s duo cone seals are mainly available in two steel grades: one is high chromium molybdenum (FC15Cr3Mo) and the other is Ni Hard (high-nickel alloy). Both are engineered to withstand extreme wear and corrosion in demanding engineering environments. So, if you are looking for a face seal that is going to work just as hard as you do and will keep your equipment running longer and more efficiently, Decent Machinery is the sealing specialist for you!

All About Duo Cone Seal

Duo cone seals are a type of mechanical seal composed of a pair of metal rings and toric loaders. These seals function to prevent oil leakage from the transmission system (such as shafts, wet brakes, final drives, etc.), while also blocking the external contaminants. This means these mechanical face seals also help protect the rotating components of the equipment from excessive wear and damage by foreign materials during operation.

What Else Are Duo Cone Seals Called?

Duo cone seals are known by a list of other names, depending on the industry and manufacturer. Common alternatives include face seals, mechanical face seals, HDDF heavy duty seals, toric seals, metal face seals, face seals, dynamic face seals or floating seals.

What Types Of Floating Seals are there?

- DO Type Face Seals: The DO type is the most common form of floating seal. It uses a toric elastomer.

- DF Type Face Seals: Same as HDDF, this type is mainly developed for heavy-duty applications. Instead of an O-ring, the Trapezoid elastomer toric ring serves as the second sealing element.

Each seal type includes two metal seals combined with elastomers. They are installed face to face in two separate housings. When in operation, only one half of the duo cone seal rotates, while the other half remains static.

Application Advantages of Dual Cone Seals

The dual cone seal stands out among many sealing products due to its significant application advantages:

| Simple Structure, Reduced Machine Maintenance Frequency: | The dual cone seal features a relatively simple structure. By selecting high-quality dual cone seals, machine maintenance due to oil leakage can be significantly reduced. To ensure proper Installation, a dedicated tool is needed to prevent any misalignment or uneven pressure that could shorten the product’s service life. |

| Wide range of applications: | This seal structure is suitable for higher pressures, temperatures, and larger diameters, meeting the needs of various complex working conditions. |

| Stable sealing performance: | Due to the self-tightening action, the dual cone seal can maintain good sealing performance under little pressure and temperature fluctuations, ensuring the safe operation of the equipment. |

In summary, dual cone seals, with their distinctive working principle and durability in severe environments, play an increasingly important role in the modern engineering industry. Built on a promise of quality and integrity, Decent Machinery continues to be a trusted and efficient partner for global customers.

Why Choose Decent Machinery as Best Duo Cone Seal Suppliers?

At Decent Machinery, we pride ourselves on delivering top-quality products and services to our customers. When your machine goes down, we understand the urgency of getting it back up and running as soon as possible. That is why our sealing experts will work closely with you to identify the best-suited duo cone seals for your specific equipment. Don’t have a part number? Not a problem! With our outstanding expertise, we can help you find exactly what you need in no time at all.

Decent Machinery is also pleased to offer next-day shipping on standard orders. That’s why you are guaranteed prompt and efficient service because our goal is to get your heavy-duty seals to you as quickly as possible!

FAQs on Duo Cone Seal Suppliers

Q1. What is a duo cone seal?

A: Duo Cone seal is a proven shaft sealing solution designed for rotating equipment and heavy-duty machinery.

Q2. What must a duo cone seal be resistant to?

A: Duo cone seals or face seals are designed for rotating applications in harsh environments. They are built to withstand heavy wear and prevent entry of abrasive external contaminants. In addition, they offer considerable corrosion resistance and operate reliably under a wind range of temperatures.

Q3. How does a duo cone seal work, and what material is it made of?

A: A duo cone seal group consists of two metal seals and two flexible toric rings that form a tight seal by axial force. The metal parts from Decent Machinery are made of FC15Cr3Mo cast iron and Ni Hard (high-nickel alloy). The toric rings,serving as secondary seals, are typically made from NBR, VMQ, HNBR, and FKM.

Q4. What is the function of a duo cone seal?

A: The duo cone seal functions to protect the shaft and inner parts against wear and tear. Moreover, the seal helps to prevent any leakage from the inner to the external part.